MULTI-DOF technology from HEIDENHAIN gives hybrid bonding a boost

Higher accuracy and greater throughput

To handle the development of artificial-intelligence systems, semiconductor technology required a transition from monolithic chip structures to a chiplet approach. Modularity and the allocation of functions across individual chiplets were key factors in the rapid computing-power advances needed since the beginning of the 2020s. Notably, the chiplet approach goes hand in hand with greater production miniaturization. Whereas electrical-contact distances of 10 µm and thus accuracies of 1 µm were still the chipmaking standard in 2010, these metrics are currently at 2 µm and 200 nm, with the industry demanding even greater optimization in order to realize applications such as chips for humanoid robots and self-driving vehicles.

But the chiplet approach isn’t just about ever greater miniaturization: While a reduction in production throughput had been an acceptable compromise for smaller structures in previous years, a significant increase in productivity is now back on the agenda of semiconductor manufacturers. HEIDENHAIN encoders with MULTI-DOF TECHNOLOGY unlock these new dimensions of higher accuracy and performance.

HEIDENHAIN Dplus encoders for front-end, mid-end and back-end processes

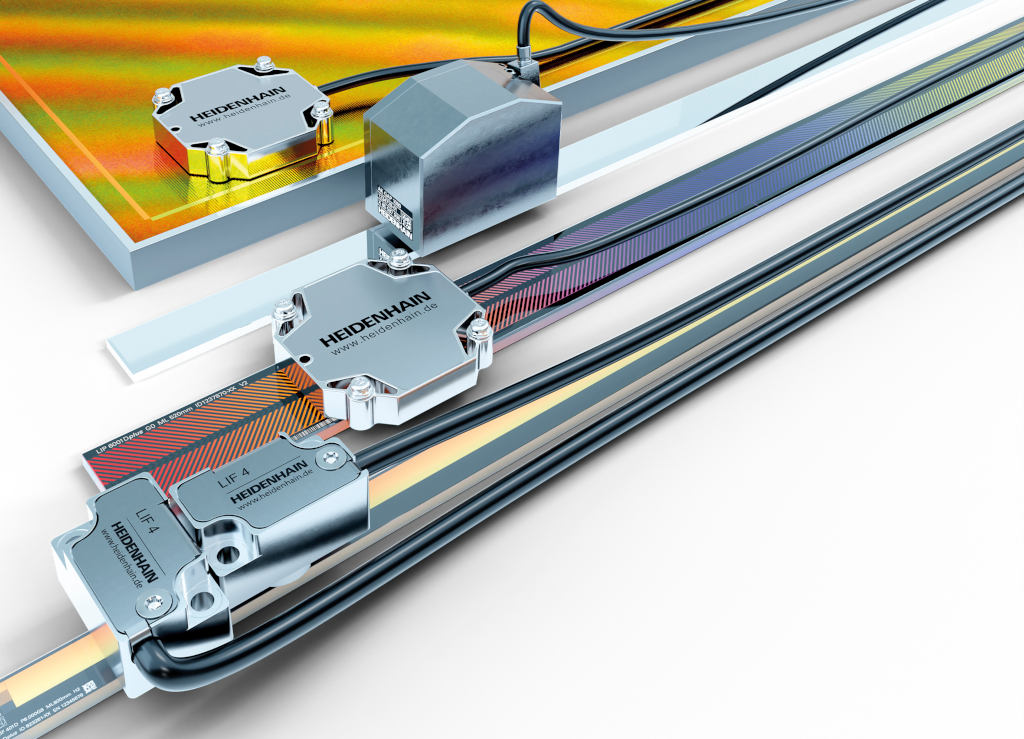

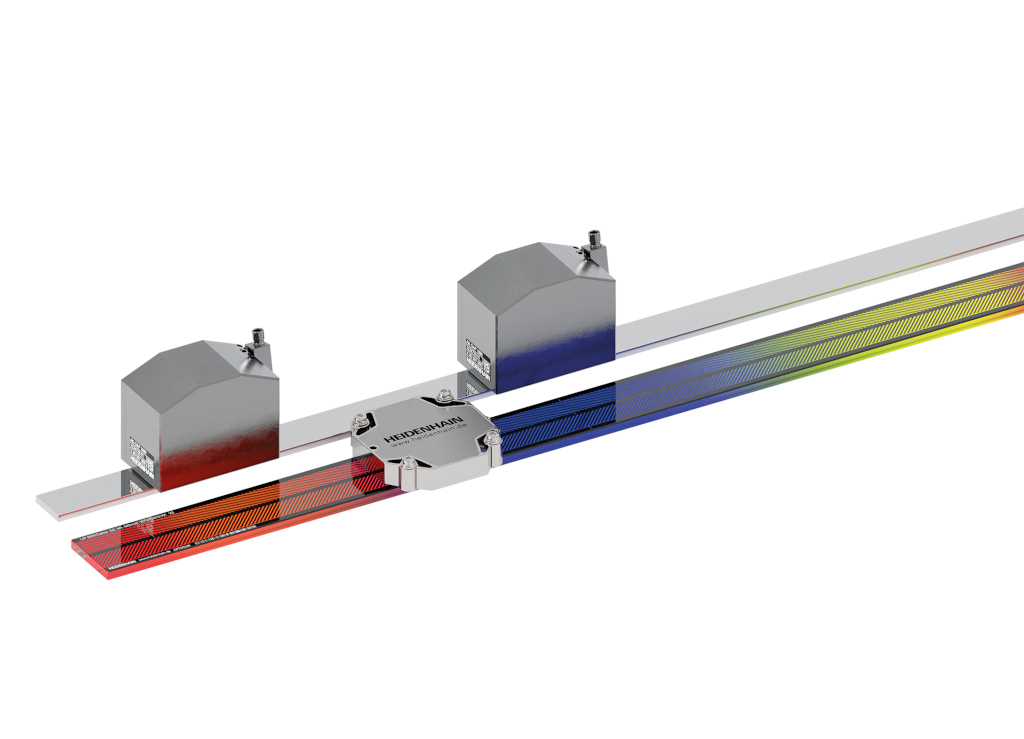

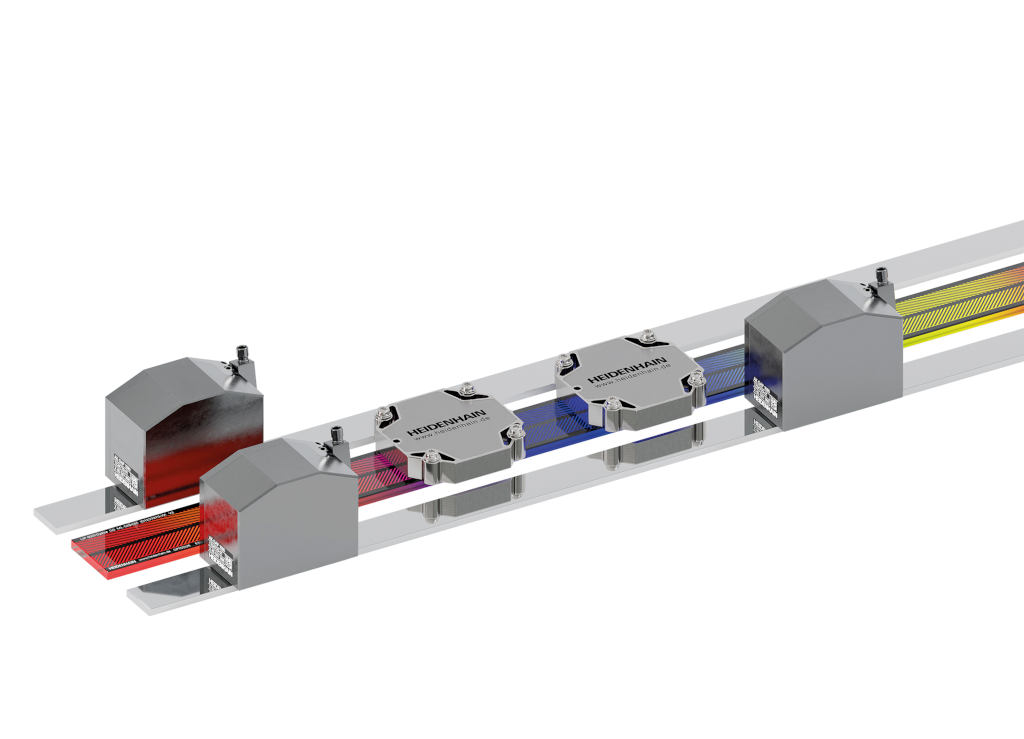

High-performance encoders from HEIDENHAIN are used in all areas of semiconductor and electronics production, encompassing front-end manufacturing, back-end production and the new mid-end processes needed for chiplet technology. Through this longtime experience, HEIDENHAIN has acquired strong expertise in the unique requirements and trends of electronics and semiconductor manufacturing, thus giving rise to its MULTI-DOF TECHNOLOGY. Encoders with this technology can capture up to six degrees of freedom in addition to their primary axis of measurement. Due to their multi-dimensional feedback, these encoders are known by the designation “Dplus”.

MULTI-DOF technology for positioning accuracy better than 200 nm

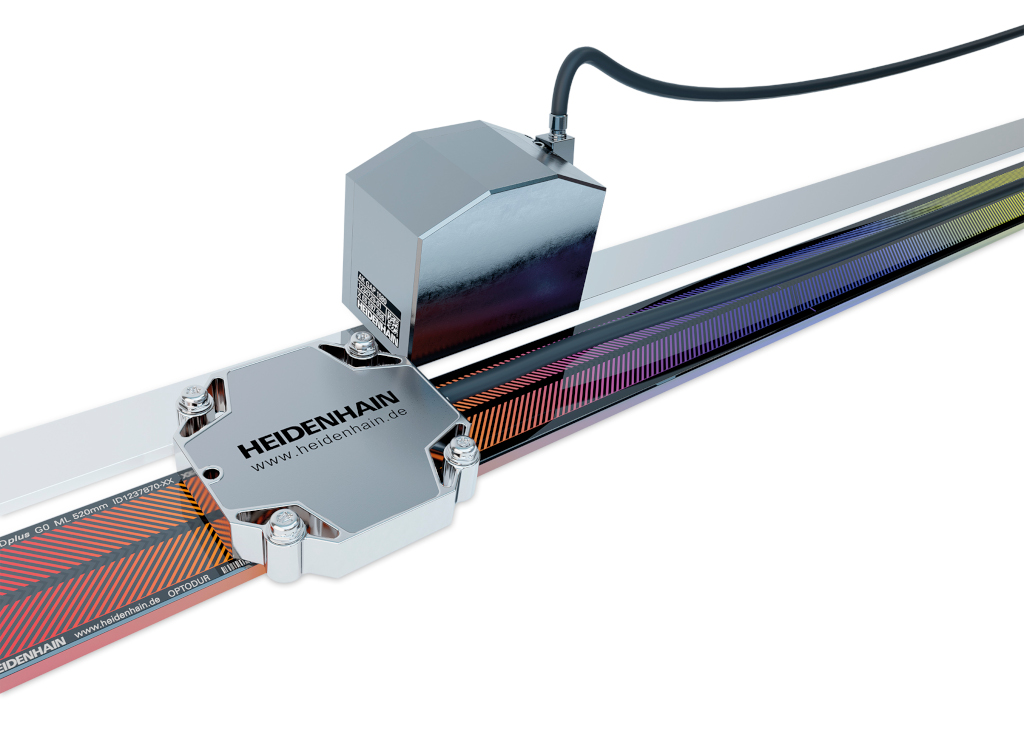

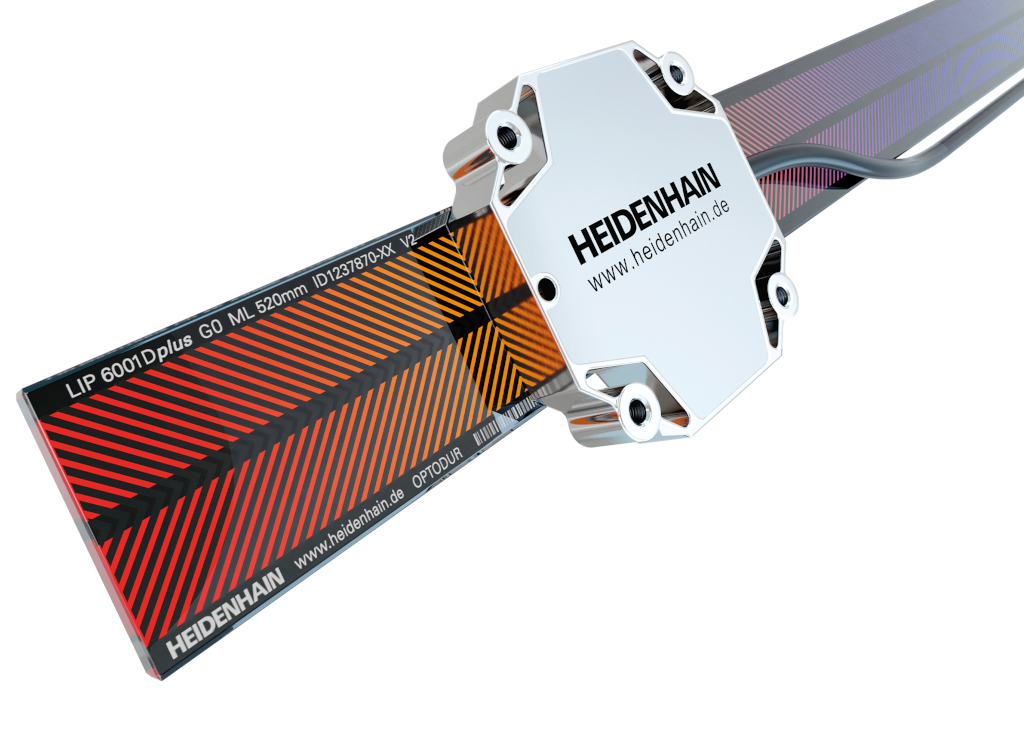

By measuring motion in additional degrees of freedom, MULTI-DOF encoders can detect and compensate for inaccuracies that are unavoidable in the real world. These include thermal influences and straightness deviations in linear guideway accuracy, not to mention manufacturing and assembly tolerances. Collecting this data simultaneously increases positioning accuracy and dynamic performance. Even the simplest MULTI-DOF solution, consisting of the LIP 6000 Dplus exposed linear encoder and two scanning heads for recording two degrees of freedom, can achieve position accuracies better than 1 µm at up to 5 kUPH. Since each additional degree of freedom entails an accuracy improvement, positioning accuracies considerably better than the current 200 nm will become possible.

A single source for complete production systems

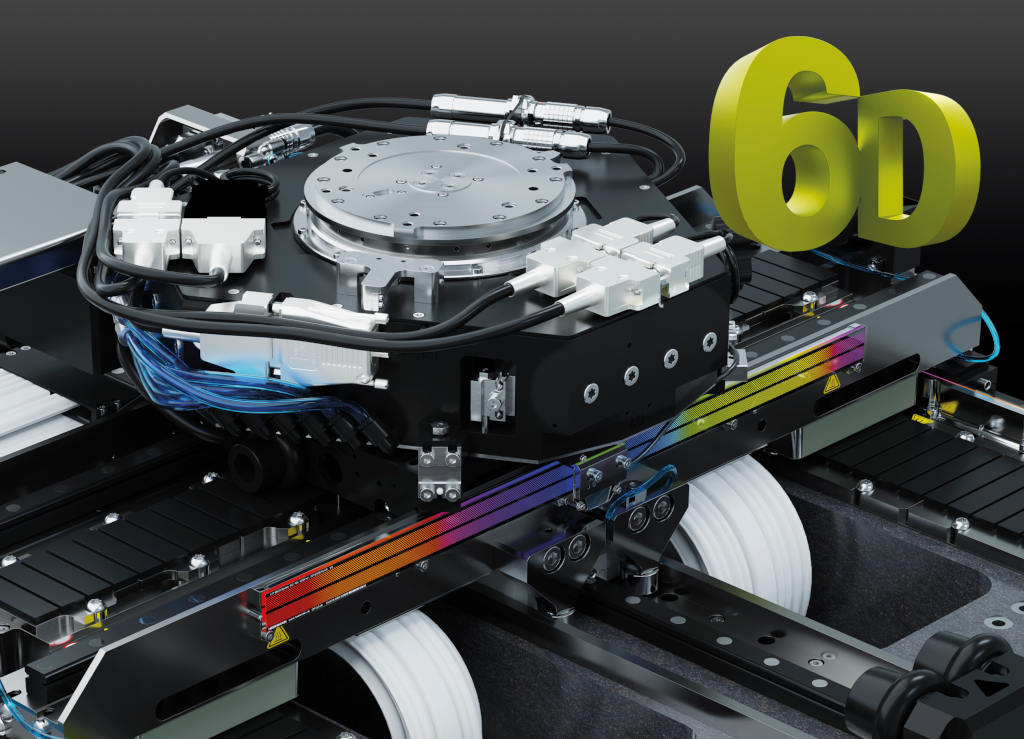

To leverage this increase in accuracy and dynamic performance, manufacturing equipment must simply fulfill the standard requirements that apply to conventional HEIDENHAIN LIP 6000 encoders. Installation and operation of Dplus encoders with MULTI-DOF TECHNOLOGY is identical to that of conventional encoders. In fact, the Dplus encoders may even be more convenient because HEIDENHAIN can deliver fully built and calibrated assemblies that ensure complete transfer of the encoder’s absolute accuracy to the customer’s application. Thanks to this TRANSFERABLE ACCURACY concept from HEIDENHAIN, encoders can achieve their certified accuracy regardless of the mounting conditions, tilting loads and exogenous factors such as vibration, sudden physical loads and temperature fluctuations, thus improving both accuracy and performance. Meanwhile, high-end motion systems from ETEL combine HEIDENHAIN encoders, powerful direct-drive motors, high-performance motion and position controllers, and pioneering vibration isolation solutions to create complete platforms for wide-ranging applications such as front-end process monitoring, advanced packaging and component testing.

The EnDat 3 interface: future-ready for digital manufacturing

The EnDat 3 interface from HEIDENHAIN offers numerous benefits for MULTI-DOF applications. A major advantage is its ability to calculate and transmit all relevant position values over a single cable. The interface also features EnDat system information. This electronic ID label provides information about the encoder and the larger system, allowing automatic encoder setup and even automatic setup of the larger system if system data storage is implemented by the OEM. EnDat 3 also offers numerous benefits for integrating external sensors and online diagnostics by transmitting temperature-sensor, condition-monitoring and predictive-maintenance data to motion or position controllers in the production systems of the electronics and semiconductor manufacturing industry.